|

| Commodity Plastic |

Commodity plastic is a

term frequently used in the plastics industry to refer to a group of plastics

that are produced on a large scale and used in a wide range of applications.

Understanding the basics of commodity plastic, including its properties and applications,

is essential for anyone involved in the manufacturing or use of plastic

products.

Exploring the Basics of

Commodity Plastic:

- Definition and Characteristics:

Commodity

Plastic refers to a category of plastics that are produced in high

volumes and have relatively low costs compared to engineering plastics or

specialty plastics. These plastics are characterized by their versatility,

durability, and ease of processing, making them ideal for a variety of

applications.

- Common Types of Commodity Plastics:

Some of the most common types of commodity plastics include polyethylene

(PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), and

polyethylene terephthalate (PET). Each type of commodity plastic has its

own unique properties and applications, ranging from packaging materials

to consumer goods.

Applications of

Commodity Plastic:

- Packaging:

One of the largest applications of commodity plastic is in packaging

materials. Polyethylene and polypropylene, in particular, are widely used

for manufacturing plastic bags, bottles, containers, and packaging films

due to their excellent barrier properties and flexibility.

- Consumer Goods:

Commodity plastic is also commonly found in a wide range of consumer

goods, including household items, toys, kitchenware, and electronics.

Polystyrene, for example, is used to make disposable cups, plates, and

food containers, while polyvinyl chloride is used in the production of

vinyl flooring and window frames.

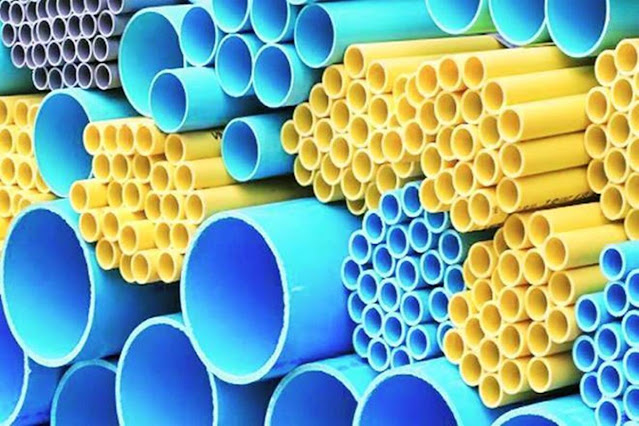

- Construction Materials:

In the construction industry, commodity plastic is used for manufacturing

a variety of materials, such as pipes, fittings, insulation, and siding.

PVC, in particular, is a popular choice for plumbing and drainage systems

due to its corrosion resistance and affordability.

- Automotive Components:

Commodity plastics play a vital role in the automotive industry, where

they are used for manufacturing interior and exterior components, such as

dashboards, bumpers, trim panels, and seating. Polypropylene, with its

lightweight and impact-resistant properties, is a common choice for

automotive applications.

Commodity plastic is a

versatile and widely used material that plays a crucial role in various

industries and applications. Understanding the basics of commodity plastic,

including its properties and applications, is essential for manufacturers,

designers, and consumers alike. By recognizing the versatility and value of

commodity plastic, we can continue to innovate and create sustainable solutions

for the future.