|

| Track And Trace Solutions |

Understanding the Track and Trace Landscape

Track and trace has become increasingly important across industries in order to maintain supply chain visibility and compliance with regulations. The pharmaceutical industry was one of the early adopters of serialization and aggregation to address counterfeit drugs and other issues. However, track and trace is now a concern for many other sectors such as food and beverage, consumer goods, and more. As regulations have expanded on requirements for tracing products throughout the supply chain, companies have had to find effective solutions to manage serial numbers, aggregation and tracing capabilities.

The Current Track And Trace Solutions landscape involves solutions from various technology providers to address serialization, aggregation, traceability and visibility needs. Larger pharmaceutical and life sciences manufacturers typically have sophisticated in-house systems that integrate across their extensive supply networks. However, smaller and mid-sized brands often rely on third-party track and trace platforms to cost-effectively meet requirements. These external solutions range from basic cloud-based tracking to comprehensive full system capabilities. As needs and regulations evolve, players across the track and trace space continue enhancing their product features and functionality.

Utilizing Serialization for Compliance

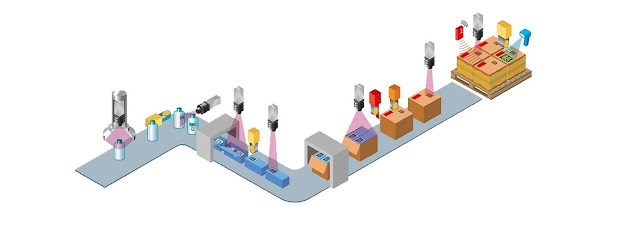

A core part of any track and trace program involves applying unique serial numbers to products at the individual item or packaging level. This process, known as serialization, creates the foundation for tracing single items through the supply chain and facilitates aggregation of data at higher package configurations. Serial numbers must be generated, printed or marked, and associated with key product details in tracking systems or databases. Advanced solutions support numerous numbering standards and flexible options for integrating serialization processes into packaging lines.

Being able to serialize efficiently and accurately is essential for maintaining compliance with track and trace regulations. Solutions are able to analyze serialization performance, identify issues and help ensure all required products leave facilities with the correct unique IDs applied. This level of control and reporting provides confidence that tracking can occur properly downstream. Integration with existing enterprise resource planning (ERP) and manufacturing systems allows serialization data to flow seamlessly throughout operations.

Aggregating Data for Full-Case Visibility

Once pharmaceuticals, food products and other goods are serialized at the unit level, the next critical capability involves aggregating this item-level tracking data as packaging configuration and cases change. As individual items are bundled into larger packages like bottles, bundles and pallets, their underlying serial numbers need to be associated and consolidated up the packaging hierarchy. This aggregation creates logical linkages between products at all stages to give complete traceability of full cases and shipping units.

Leading track and trace solutions make aggregation a streamlined part of the overall supply chain digital thread. Flexible configuration options allow matching how software represents and groups physical packaging constructs. Integration points capture this bundling of serial numbers as it occurs. Automated validation checks ensure accurate aggregation. Embedded business intelligence and visualization tools then make the associated product information useful for things like inventory monitoring, recall management and compliance auditing. The end result gives stakeholders up and downstream full case-level traceability while serial numbers remain linked individually.

Transforming Tracking Workflows

To truly transform operations, modern track and trace platforms aim to seamlessly integrate across existing workflows rather than impose disruptive change. Case in point, flexible mobile and handheld capabilities allow real-time tracking tasks to occur where work happens rather than needing to migrateto fixed workstations. Devices can read barcodes, capture images and collect signatures on the production floor, in warehouses and during transportation. Edge connectivity enables these mobile operations to still benefit from centralized software functions and data management.

Additionally, embedded analytics and business intelligence tools provide actionable insights alongside core tracking functions. Dashboards, views and reports give custom visibility into metrics like trace execution times, failure rates, product expiration status and more. Having critical data and KPIs readily available helps drive continuous improvement. Artificial intelligence is also playing an increasing role, such as through automated anomaly detection to flag potential issues. All of these advanced features work to optimize existing processes around track and traceinstead of replacing them.

Ensuring End-to-End Traceability

While internal operations are a big focus, track and trace solutions must also facilitate sharing product journey data seamlessly throughout intricate supply chain networks. Integration capabilities allow sharing tracking events securely bidirectionally between manufacturer, distributor, retail and other trading partner systems. Open application programming interfaces (APIs) further broaden these connectivity options, including to third-party logistics (3PL) providers, carriers and customs agencies involved with transportation. Blockchain initiatives also show promise for establishing tamper-proof distributed ledgers of traceability records.