|

| Commodity Plastic |

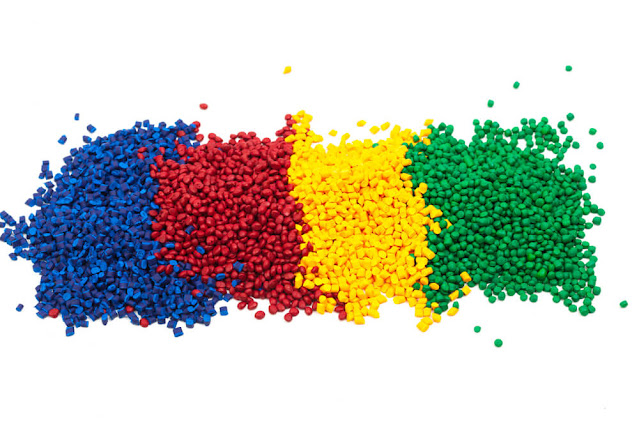

Commodity plastic, a

term referring to common, widely-used plastics, finds its way into numerous

facets of modern life due to its versatility and affordability. Let's delve

into some of the key uses and applications of commodity plastic across various

industries.

- Packaging Industry:

Commodity plastic plays a pivotal role in the packaging industry, where it

is utilized to create containers, bottles, films, and wraps for storing

and transporting goods. Its lightweight nature, durability, and

cost-effectiveness make it an ideal choice for packaging a wide range of

products, from food and beverages to consumer goods and pharmaceuticals.

- Automotive Sector:

In the automotive sector, commodity plastic is extensively used in

interior and exterior components, such as dashboards, door panels,

bumpers, and trim. Its ability to be molded into complex shapes,

resistance to impact and corrosion, and lightweight properties contribute

to its popularity in vehicle manufacturing, where it helps improve fuel

efficiency and reduce overall vehicle weight.

- Construction and Building Materials:

Commodity

Plastic finds applications in the construction industry for

various building materials, including pipes, fittings, insulation, and

siding. Its versatility, durability, and resistance to moisture,

chemicals, and corrosion make it suitable for both interior and exterior

construction projects, contributing to the longevity and sustainability of

structures.

- Consumer Goods:

From household appliances and electronics to toys and furniture, commodity

plastic is ubiquitous in the production of consumer goods. Its

moldability, affordability, and wide range of available colors and

textures make it a popular choice for manufacturers seeking to create

functional and aesthetically pleasing products for everyday use.

- Medical and Healthcare Products:

In the medical and healthcare sectors, commodity plastic is used to

manufacture a variety of products, including medical devices, equipment

components, packaging for pharmaceuticals, and disposable supplies such as

syringes and IV bags. Its biocompatibility, sterilizability, and ability

to meet stringent regulatory requirements make it indispensable in

healthcare settings, where safety and hygiene are paramount.

- Electronics and Electrical

Components: Commodity plastic is also

prevalent in the electronics industry, where it is used to produce

casings, housings, connectors, and insulation for electrical and

electronic devices. Its electrical insulation properties, heat resistance,

and ability to withstand harsh environmental conditions make it an

essential material for protecting and housing sensitive electronic

components.

Commodity plastic

serves as a versatile and indispensable material across a wide range of industries,

contributing to the functionality, durability, and affordability of countless

products and applications. From packaging and automotive components to

construction materials and medical devices, its widespread use underscores its

importance in modern manufacturing and everyday life.