|

| Single Use Assemblies |

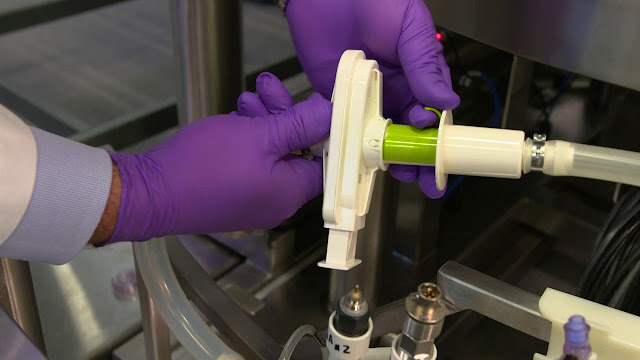

Single Use Assemblies

have emerged as a transformative solution in biopharmaceutical manufacturing,

offering unparalleled flexibility, efficiency, and cost-effectiveness. These

innovative systems, designed for single-use applications, have revolutionized

the production process, enabling biopharmaceutical companies to streamline

operations, minimize cross-contamination risks, and accelerate time-to-market.

Single Use Assemblies,

also known as disposable systems, represent a paradigm shift in bioprocessing

technology. Unlike traditional stainless-steel assemblies, which require

extensive cleaning, validation, and sterilization between batches, Single Use

Assemblies are designed for one-time use, eliminating the need for cleaning and

reducing downtime between runs. This not only simplifies operations but also

minimizes the risk of product cross-contamination, ensuring product integrity

and quality.

The adoption of Single

Use Assemblies offers several key advantages for biopharmaceutical

manufacturers. Firstly, these assemblies enable greater process flexibility,

allowing manufacturers to quickly adapt to changing production demands and

scale operations as needed. With Single Use Assemblies, biopharmaceutical

companies can easily transition between different products and production

scales without the need for costly and time-consuming equipment changeovers.

In addition to

flexibility, Single Use Assemblies offer significant cost savings compared to

traditional stainless-steel systems. The upfront capital investment required

for stainless-steel equipment, including installation, maintenance, and

validation, can be prohibitively high. Single Use Assemblies, on the other

hand, eliminate these capital expenditures, allowing manufacturers to allocate

resources more efficiently and reduce overall production costs.

Furthermore, Single Use

Assemblies help mitigate the risk of product contamination and ensure product

safety and purity. With traditional stainless-steel systems, there is always a

risk of residual product or cleaning agents remaining in the equipment, leading

to cross-contamination and compromising product quality. Single Use Assemblies

eliminate this risk by providing a sterile, single-use solution for each batch,

thereby safeguarding product integrity and compliance with regulatory

standards.

Another key benefit of

Single Use Assemblies is their scalability. Biopharmaceutical manufacturing

processes often require flexibility in production scale, ranging from

laboratory-scale research and development to large-scale commercial production.

Single Use Assemblies can be easily scaled up or down to accommodate different

production volumes, allowing manufacturers to optimize resources and meet

market demand more effectively.

Moreover, Single Use

Assemblies offer environmental sustainability benefits compared to traditional

stainless-steel systems. By eliminating the need for extensive water and energy

consumption associated with cleaning and sterilization processes, Single Use

Assemblies reduce the overall environmental footprint of biopharmaceutical

manufacturing operations. Additionally, many Single Use Assemblies are designed

for recycling or disposal, further minimizing waste generation and promoting

sustainable practices.

Single Use Assemblies

represent a significant advancement in biopharmaceutical manufacturing

technology, offering unmatched flexibility, efficiency, and cost-effectiveness.

By eliminating the need for cleaning and sterilization between batches, Single

Use Assemblies streamline operations, minimize cross-contamination risks, and

accelerate time-to-market for biopharmaceutical products. As the demand for

biopharmaceuticals continues to grow, Single Use Assemblies will play an

increasingly critical role in meeting production challenges and driving

innovation in the industry.