|

| Conformal Coating Stripper |

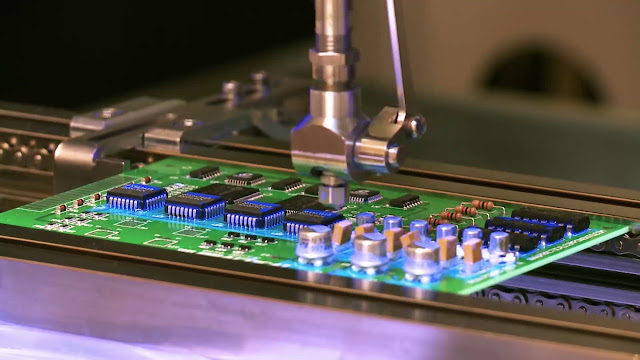

Conformal coatings are widely used in the electronics industry to protect

printed circuit boards and components from various environmental hazards.

However, there are times when the protective coating needs to be removed - for

repairs, rework or replacement of components. This is where conformal coating

strippers come into play.

What is a Conformal Coating Stripper?

A conformal coating stripper, as the name suggests, is a chemical solvent that

is specifically designed and formulated to remove conformal coatings from

printed circuit boards and electronics assemblies. Conformal coatings such as

acrylic, polyurethane, silicone etc. form a protective layer over the PCB to

shield it from moisture, chemicals, dust and other environmental contaminants.

However, this protective layer needs to be removed during circuit repairs.

That's where conformal coating strippers come in - they dissolve and remove the

protective conformal coating layer without causing any damage to the underlying

PCB or components.

Types of Conformal Coating Strippers

There are different types of Conformal

Coating Stripper available in the market depending on the type of

coating they are designed to remove:

- Acrylic strippers - Used for removing acrylic based conformal coatings. They

contain solvents like Methyl Ethyl Ketone (MEK) and acetone.

- Polyurethane strippers - Formulated with chemicals like dimethylformamide

(DMF) and N-methyl pyrrolidone (NMP) to remove polyurethane conformal coatings.

- Silicone strippers - Contain solvents such as trichloroethylene and methylene

chloride that effectively dissolve silicone coatings.

- Universal/Multipurpose strippers - Can remove multiple conformal coating

types like acrylic, polyurethane and silicone in one go. However, they may not

be as effective as coating-specific strippers.

Apart from type, strippers also differ in form - liquids, gels, wipes and

aerosols. Liquid strippers need to be applied using brushes or swabs while

gels, wipes and aerosols provide a cleaner application.

How do Conformal Coating Strippers Work?

The mechanism through which conformal coating strippers remove the protective

layer is through dissolution and weakening of polymer bonds present in the

coating material. Here are the basic steps:

- The stripping solvent is applied to the coated surface using a brush, swab or

spraying.

- The solvent penetrates into the conformal coating layers through the

capillary action.

- It interacts with the polymer molecules in the coating via dissolution,

causing the bonds between them to break.

- As the polymer bonds weaken and break, the coating loses its adhesive

properties and integrity. It then flakes or rolls off the PCB in the form of a

gel or liquid.

- Residual coating material is removed using solvent wipes or spraying followed

by thorough drying.

Factors Affecting Stripping Efficiency

Several factors determine how effectively a stripping solvent can remove a

conformal coating:

- Type of coating - Coating-specific strippers work best as they are formulated

for that polymer.

- Temperature - Higher temperatures aid the stripping process by increasing the

solvent penetration and reaction kinetics.

- Application technique -Thorough and liberal application ensures better

penetration for complete stripping.

- Dwell time - Allowing sufficient time for the solvent to interact with

coating improves results.

- Mechanical aid - Agitation using brushes releases more firmly bonded

coatings.

-Coating curing and thickness - Fully cured or thick coatings may require

multiple applications or abrasion.

Safety With Conformal Coating Strippers

While conformal coating strippers effectively remove protective coatings,

proper safety precautions must be followed as most contain hazardous chemicals:

- Use in well-ventilated areas or with fume extraction to prevent inhalation of

toxic vapors.

- Wear gloves, goggles for skin and eye protection against risk of irritation

or damage.

- Store and dispose stripping wastes as per environmental regulations to

prevent groundwater contamination.

- Follow material safety data sheet guidelines for handling, application and

first aid in case of accidental exposure.

- Consider shifting to less toxic, environment-friendly natural or water-based

strippers where possible.

Conclusion

In conclusion, conformal coating strippers are indispensable chemicals in the

electronics repair and rework industry. By understanding their mechanisms,

types, factors affecting performance and safety guidelines, technicians can

select the right strippers to remove coatings efficiently and protect equipment

as well as themselves during the stripping process. With growing environmental

consciousness, safer alternatives to hazardous strippers are also gaining

traction.

Get More Insights On This Topic: Conformal

Coating Strippers Market