|

| Conformal Coatings |

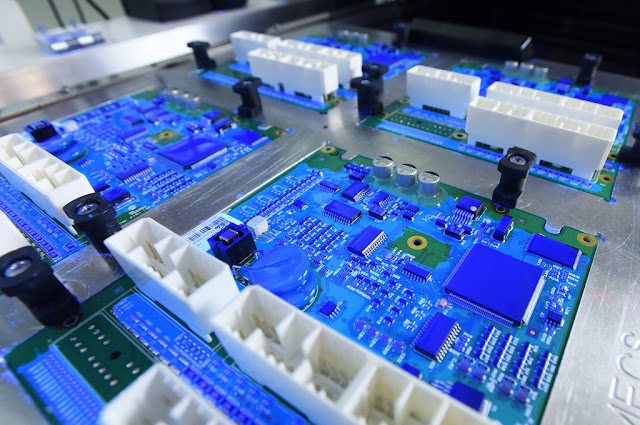

Conformal coatings are thin protective coatings that are applied to

printed circuit boards and other electronic components to help protect them

from various environmental factors. As electronics become more miniaturized and

compact, conformal coatings play an increasingly important role in protecting

delicate components and preventing failures.

Types of Conformal Coatings

There are several different types of conformal coating materials that are

commonly used, with each having their own advantages and applications.

Acrylic Coatings

Acrylic conformal coatings are some of the most widely used coating materials.

They offer good moisture and chemical resistance along with abrasion

resistance. Acrylic coatings cured at room temperature are fast drying but

offer less protection than thermally cured varieties. Fully cured acrylic

coatings can withstand temperatures up to 150°C.

Silicone Coatings

Silicone conformal coatings are more expensive than acrylic but offer excellent

flexibility and thermal shock resistance. They can withstand continuous

operating temperatures as high as 200°C. This makes them well suited for

applications in harsh environments or with frequent temperature fluctuations.

Different types of silicone coatings such as moisture cure and UV cure are

available.

Urethane Coatings

Urethane Conformal

Coatings fill the gap between acrylics and silicones by offering

performance in between the two. They are flexible like silicones but less

expensive. Urethane coatings can withstand temperatures from -50°C to 150°C and

are water resistant as well. Two part urethane coatings provide excellent

adhesion and protection.

Other Types

Other specialty conformal coating materials include epoxies, polyurethanes, and

parylene. Epoxies provide the highest level of protection against moisture and

chemicals but require high temperature curing. Polyurethanes are flexible like

silicones but can withstand up to 200°C. Parylene coatings are vapor deposited

under vacuum for a uniform pinhole-free coating, but the equipment costs are

high.

Conformal Coating Properties and Applications

The ideal conformal coating material will possess certain key properties to

protect electronic components in different environments and applications.

Protection from moisture and chemicals is critical for coatings used in harsh

and wet conditions. Resisting corrosion is important when components will be

exposed to saltwater, chemicals or humidity. Conformal coatings must exhibit

good barrier properties.

Flexibility is necessary if the coated board will experience thermal or

mechanical stresses. Rigid coatings could crack or peel. Materials like

silicone and urethane remain flexible over a wide temperature range.

Adhesion to the substrate is important to prevent the coating from flaking or

peeling off over time. Proper surface preparation and coating selection ensures

a strong bond between coating and PCB.

Dielectric strength provides insulation to prevent arcing between conductors.

High voltage electronics require a conformal coating that won't break down at

higher voltages.

Some other key properties include curing temperature which affects throughput,

voltage standing capacity, and coating thickness requirements unique to each

application.

Common applications that benefit from conformal coatings include motors and

generators, industrial equipment, avionics, automotive circuits, and consumer

appliances that experience moisture, chemicals, vibration or thermal stresses.

Military, aerospace and medical devices also rely on coated boards for enhanced

reliability.

Conformal Coating Process

The conformal coating process typically consists of the following basic steps:

1. PCB Preparation - Boards are cleansed to remove oils, fluxes and

contaminants using solvent washing or plasma etching. This promotes coating

adhesion.

2. Coating Application - Common methods include dip coating, spray coating and

selective coating using automated equipment. Automatic applicators ensure

uniform coverage.

3. Curing - Most coatings require a curing stage utilizing heat, UV light or

air drying to fully crosslink the coating material. Curing hardens and sets the

protective properties.

4. Inspection - Coated boards are visually and manually inspected to check for

defects, pinholes or thin spots before electrical testing. Automated optical

inspection may also be used.

5. Testing - Simple electrical functional checks and isolation resistance tests

are usually run initially to certify the coating process. Additional testing

like thermal shock may be required.

6. Repair - Any boards failing inspection can be reworked by selectively

removing the failed coating and reapplying in problem areas.

Proper selection of coating type along with a well-controlled and reproducible

process ensures maximum protection for electronics. Conformal coatings play a

key role in reliability and product lifetime.

Conformal coatings have become increasingly important for protecting

electronics from harsh and changing environmental conditions. The types of

coating materials, their properties and applications were discussed along with

the basic conformal coating process flow. As electronic products move to new

form factors and applications in industries like automotive, aerospace and

medtech, conformal coatings will continue evolving to meet protection needs and

improve long term reliability.

Get More Insights On This Topic: Conformal

Coatings

Explore More Related Topic: Liquid

Chromatography Mass Spectrometry (LCMS)